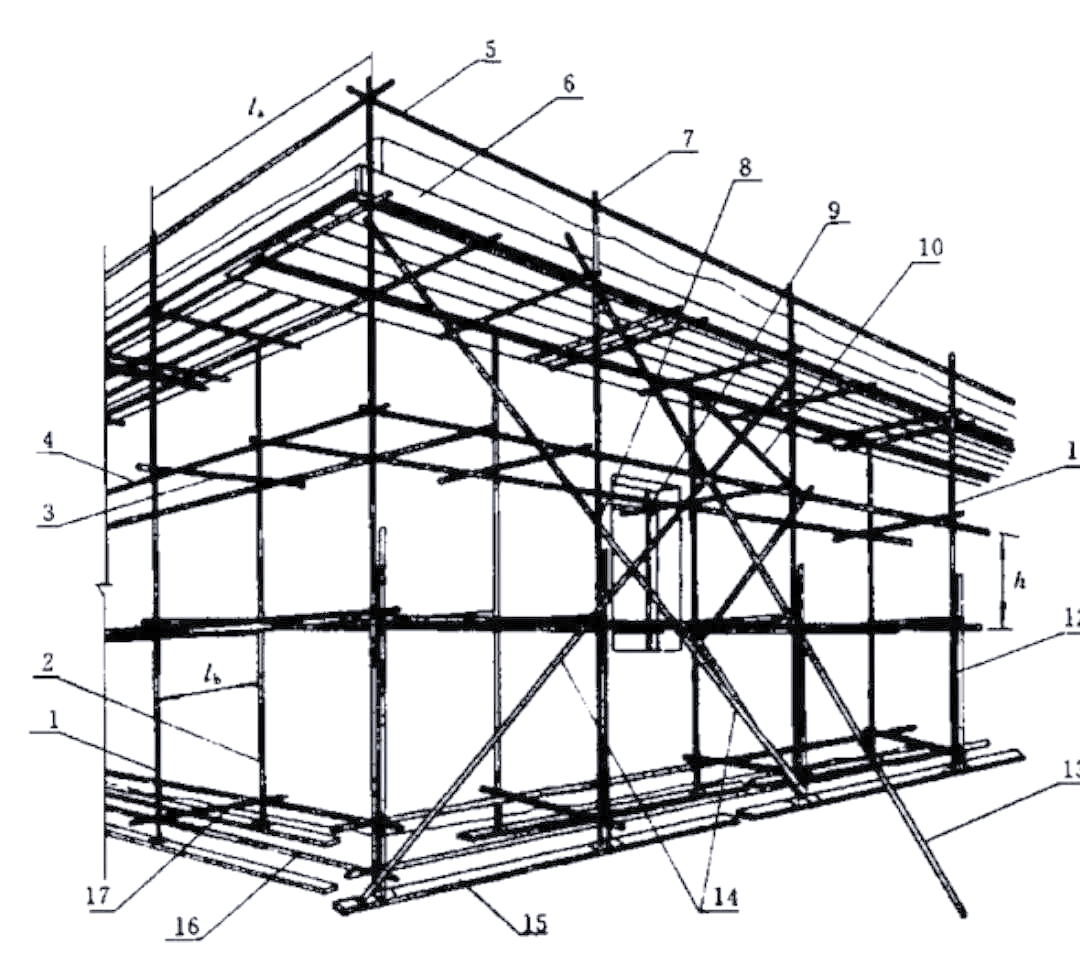

Scaffolding, an indispensable facility on construction sites, plays a crucial role in engineering construction. It not only supports the safety of construction personnel, but also serves as an important guarantee for project progress. According to different classification methods, scaffolding can be divided into various types, such as external scaffolding, internal scaffolding, full house scaffolding, and cantilever scaffolding. In addition, scaffolding can be further subdivided according to its setting form, such as single row, double row, multi row, full hall, full height, intersection circle (periphery), and special type. Next, we will use illustrations to gain a detailed understanding of the specific positions and functions of each member in the fastener type steel pipe scaffold.

Code for Construction of Longitudinal Horizontal Bars

The installation of guardrails and toe boards on the working level and ramp must comply with the following specifications

2. The longitudinal distance La of the pole is usually selected as 1.2 meters, 1.5 meters, 1.8 meters, or 2 meters.

3. The horizontal distance Lb of the upright pole is often 1.05 meters, 1.3 meters, or 1.55 meters for double row scaffolding; Single row scaffolding is often 1.2 meters or 1.4 meters in length.

4. The bottom elevation of the scaffold base should be slightly higher than the natural floor by 50 millimeters.

5. It is recommended to use wooden pads with a length covering at least 2 spans and a thickness of not less than 50 millimeters, or to use channel steel for the selection of pads.

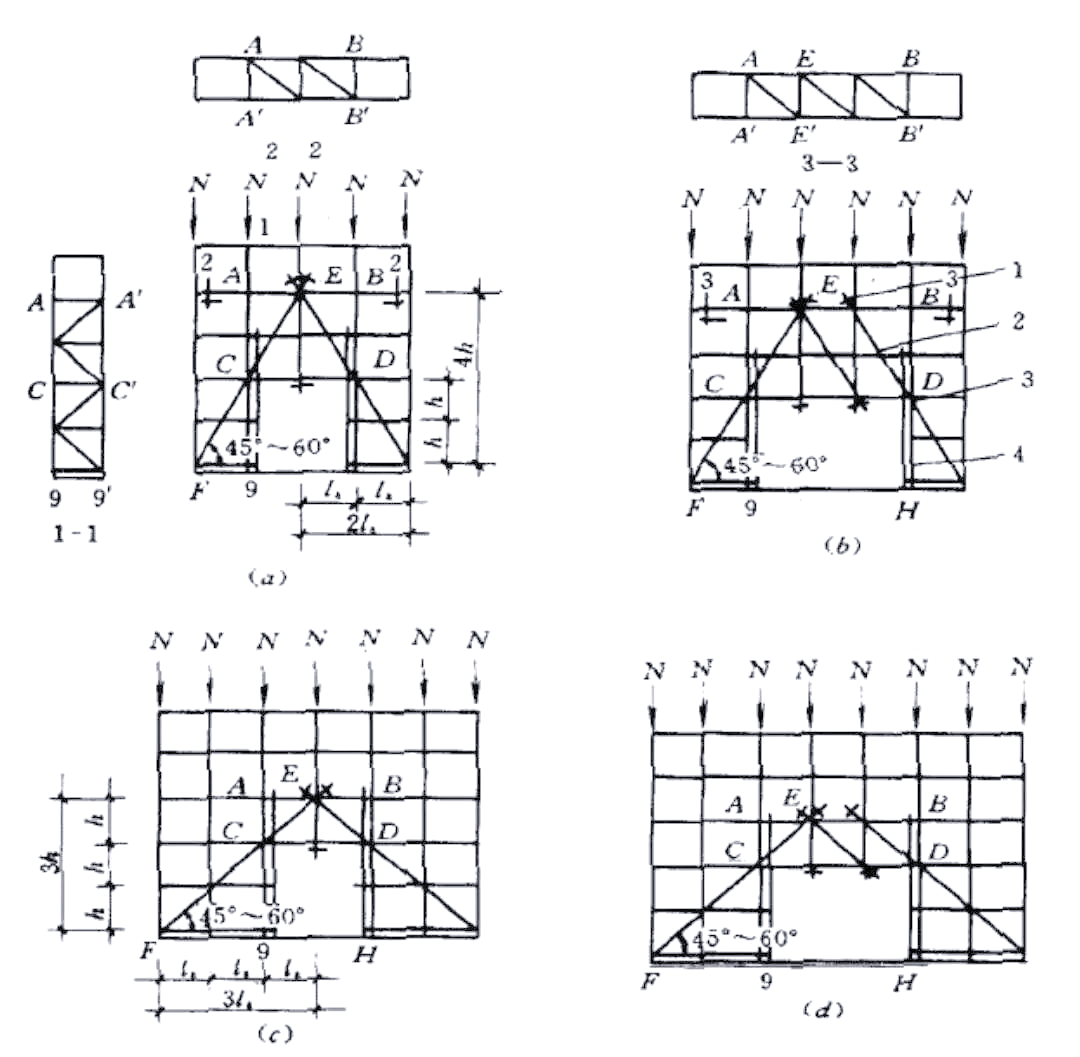

6. When the span of the scaffold is greater than or equal to 4-6 spans, diagonal braces should be installed to enhance stability.

Code for Construction of Longitudinal Horizontal Bars

The installation of guardrails and toe boards on the working level and ramp must comply with the following specifications

2. The longitudinal distance La of the pole is usually selected as 1.2 meters, 1.5 meters, 1.8 meters, or 2 meters.

3. The horizontal distance Lb of the upright pole is often 1.05 meters, 1.3 meters, or 1.55 meters for double row scaffolding; Single row scaffolding is often 1.2 meters or 1.4 meters in length.

4. The bottom elevation of the scaffold base should be slightly higher than the natural floor by 50 millimeters.

5. It is recommended to use wooden pads with a length covering at least 2 spans and a thickness of not less than 50 millimeters, or to use channel steel for the selection of pads.

6. When the span of the scaffold is greater than or equal to 4-6 spans, diagonal braces should be installed to enhance stability.

7. The partial node structure

8. If there are situations that are not explicitly stated in the specifications, reference can be made to the "Safety Technical Specification for Steel Pipe Scaffolding with Fasteners in Construction JGJ 130-2001" for operation.

Code for Construction of Longitudinal Horizontal Bars

When setting up scaffolding, the construction of longitudinal horizontal bars should follow the following points:

Code for Construction of Longitudinal Horizontal Bars

The arrangement and fixation of longitudinal and horizontal bars are crucial in the construction process of scaffolding. The following are the key points of relevant regulations:

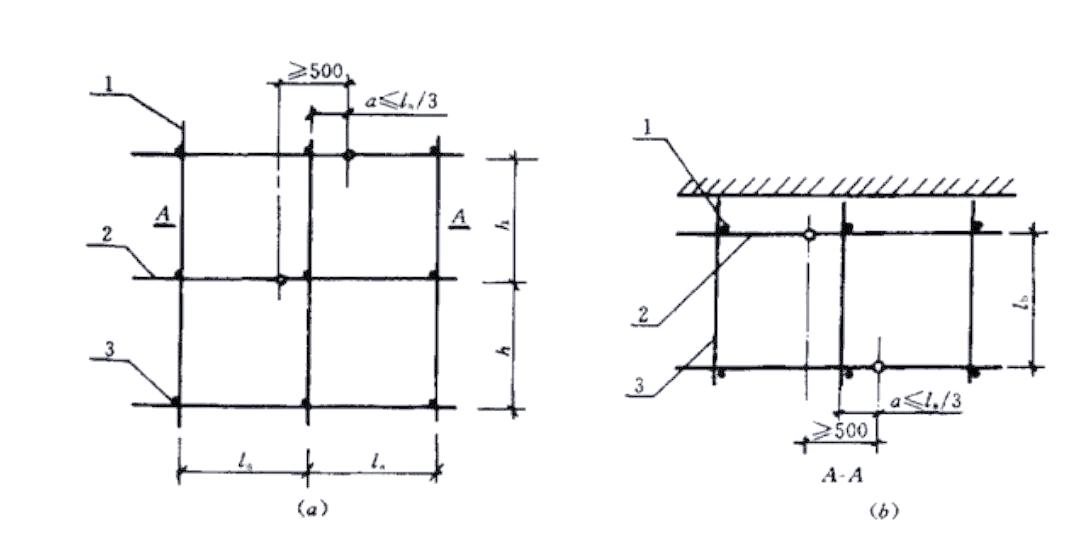

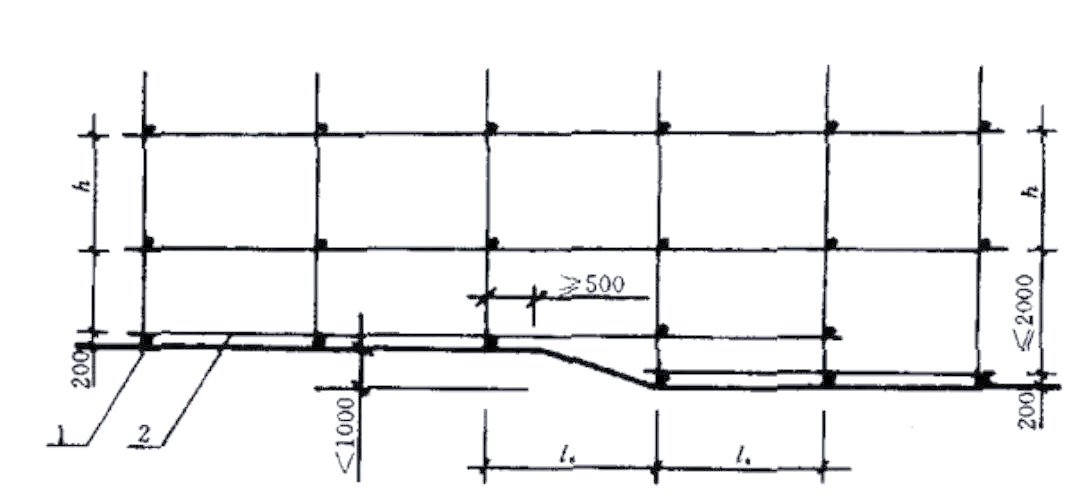

1. The longitudinal horizontal pole should be prioritized on the inner side of the upright pole, and its effective length should cover at least 3 spans.

2. The overlap length should reach or exceed 1 meter, and 3 rotating fasteners should be set at equal intervals to ensure the fixing effect. At the same time, the distance from the edge of the end fastener cover plate to the end of the overlapping longitudinal horizontal rod should not be less than 100 millimeters.

3. Except for the top step on the top floor, the joints of the uprights on all other levels and steps must be connected using docking fasteners. The specific requirements for docking and overlapping are as follows: the docking length should also not be less than 1 meter, and at least 2 rotating fasteners should be used for fixing; The distance from the edge of the end fastener cover plate to the end of the rod should also be maintained at no less than 100 millimeters.

4. The top design of the pole should ensure that it is 1 meter higher than the daughter wall surface and 1.5 meters higher than the eaves surface to ensure construction safety.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)